Company

…. moving into a garage was the second step. In the very beginning,

in 1945, Dr. Hillesheimer GmbH ”resided” in the basement of a roofless family home.

After the first “expansion” from the basement in (truly!) a garage, the company moved in 1963 into it’s first regular premises. The production site, which underwent several extensions in course of the years, today covers 1200 m2.

The foundation of Diplom-Ingenieur Dr. Hillesheimer VDE – electro-technical offices – marks the beginning of a success story which is still going strong. The newly established company produced what was required most at the time: electric appliances for household, home and offices, from small single units to complete lighting systems for shop floors together with the necessary installation switchgear.

These activities and entailing contacts led to the construction of the first electro-medical apparatus (stimulating current, micro-wave, ultra-sonic equipment). In the early fifties began the development of machines for industrial use of high-frequency (pre-heating, welding).

In 1960 business had grown to such an extend that the two main fields had to be pursued by separate firms: x-ray and medical equipment are since dealt with by PHYSIA GmbH.

The name of Dr. Hillesheimer remains inseparably linked with the development of high-frequency techniques for industrial use and it’s successful introduction into various manufacturing industries, as different from one another as automobiles, shoes and office stationery. The increasing number of applications lead to the development of an increasing variety of high-performance HF-Welding machines.

A great number of patents are documentation of the extent of inventive engineering summoned to realise new machinery and techniques for the processing and finishing of high-frequency parts. Some of them became best-sellers:

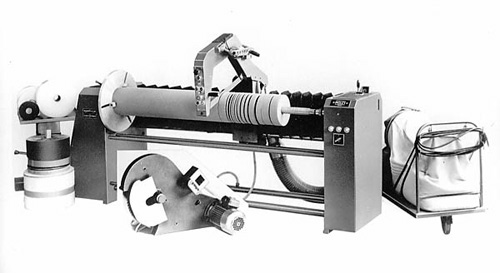

– UNITRENN (universal finishing machine),

– ROTAHIL (rotation punching machine) and, of course, the

– MOLEY® roll slitter. All of them are still fabricated (slightly different in looks and execution) and belong to the best and most successful of their “kind”.

Dr. Hillesheimer KG (“GmbH“ since 1981) grew to be a special machinery manufacturer producing equipment in small series. Today, activities concentrate on the individual manufacture of cutting machinery for specific applications as well as design, development and production of special machinery.

After sale, a wide range of product related services is available: training of operating personnel, telephone assistance and support in case of problems or questions, technical service on site, supply of spare parts, as well as regular information on new developments.

Our factory showrooms are open to customers as well as would-be customers for trials or demonstrations with their own material/s.

Every one of our machines, standard or special, is designed and built to fulfil the individual requirements of the customer, with whom we keep up a technical dialogue throughout the entire planning and manufacturing process.

No sooner than when the customer is happy with his machine will we be satisfied, too. Our customers’ appreciation supports us in our ambition to make visions come true.

If you like, we will do this for you, too.

We do not ask, whether or not it can be done …

… we start on the presumption that it is practicable, because we consider it part of our profession to offer the best possible solution to our customers’ specific demand – no matter how unusual it may appear – and to realise it.

A small team of experts, experienced specialists in different fields, tackles the problem and works out ideas and solutions using not only the most advanced methods and technical apparatus but also the know-how acquired in several decades of practice, cause a scheme which works fine in theory, under lab’ conditions and as a computer model may still turn out a flop in practice.